CNC Ictibus rectae tibiae sonum solidum carbide ictus pro ferro coolant ictus

- Depictio producti

Pro users, qui condiciones habent utendi coolant in processu, carbidi interni coolant ictus, instrui possunt ad instrumentum vitae ulterioris augendae.

OPT praebent internam coolant carbidam tapsam et latus coolant taps coolant, una postulatio utentium dependet.

juvenum coolant inservit vitali proposito, instrumentum vitae extendens in carbide tapsus.

Uno modo, interna coolant foramina directe coolant directe ad acies, reducendo incisionem caliditatis et frictionis.Hoc non solum adiuvat ad impediendam exustionem soni, sed etiam ad evacuationem chippis melioris.

Secundo, praesentia lateris coolant foraminum dispergit coolant circa scapus sonum, ulterius reducit calorem buildup et diutius vitam sonum.

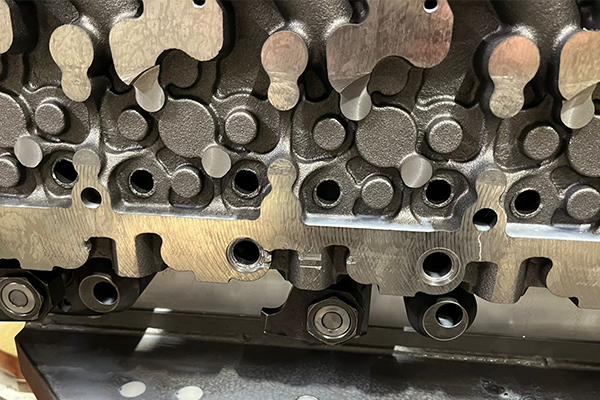

- Typicam applicationem

Una applicatio typica carbidis soni est in machinis machinis ferreis capita cylindrici.Haec capita cylindrici munere funguntur in altiore operando et diuturnitate machinarum.Cum applicatione ad tapasas carbidas, fabricantes subtilitatem filo superiores efficiunt, inde in proprietatibus auctis signandis et in casibus de ultrices reductis.Praeterea instrumentum extensum vitae carbidae sonat efficiens massam productionem efficacem, servato signis qualitatis consistentibus.

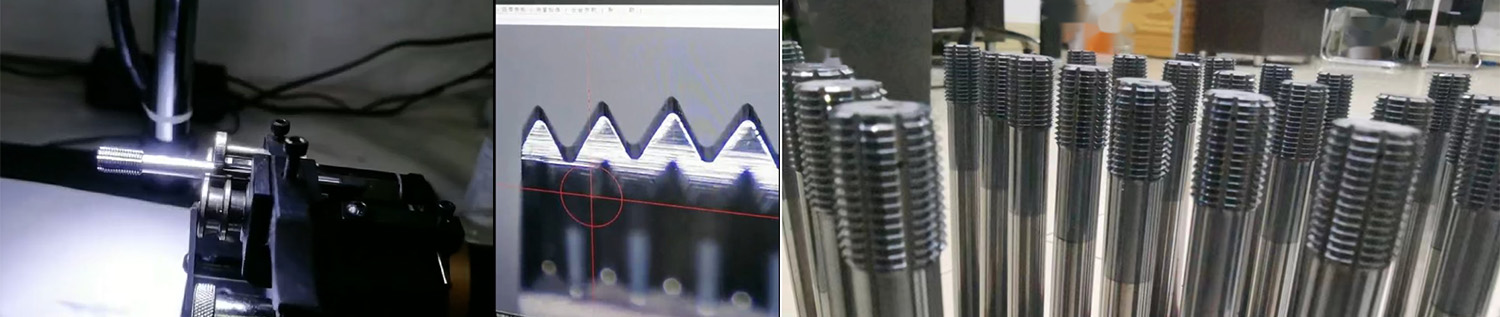

Inspectionem et ostentationem

Ante ordinationem, quaeso, communica cum servitio emptori nostro pre-venditiones;

1. Workpiece materia

2. Utrum productum est superficies tractata post processus

3. Sagaciter requisita, magnitudinem go gauge et nulla coniecturam eunt.

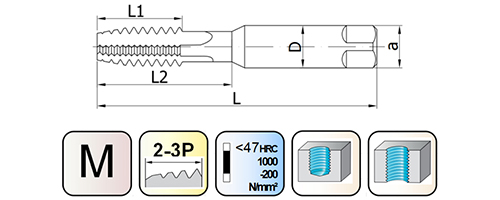

| Designatio D | Post magnitudine | picem mm | L1 mm | L2 mm | D mm | L mm | Z | a | Pre-terebra mm |

| T602-040048-M3x0.5 | M3 | 0.5 | 11 | 18 | 4 | 48 | 4 | 3.15 | 2.46-2.59 |

| T602-040050-M3.5×0.6 | M3.5 | 0.6 | 13 | 21 | 4 | 50 | 4 | 3.15 | 2.85-3.01 |

| T602-050053-M4x0.7 | M4 | 0.7 | 13 | 21 | 5 | 53 | 4 | 4 | 3.25-3.42 |

| T602-060058-M5x0.8 | M5 | 0.8 | 16 | 25 | 6 | 58 | 4 | 4.5 | 4.14-4.33 |

| T602-060066-M6x1 | M6 | 1 | 19 | 30 | 6 | 66 | 4 | 4.5 | 4.92-5.15 |

| T602-080072-M8x1 | M8 | 1 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.92-7.15 |

| T602-080072-M8x1.25 | M8 | 1.25 | 22 | 35 | 8 | 72 | 4 | 6.3 | 6.65-6.91 |

| T602-080080-M10x1 | M10 | 1 | 24 | - | 8 | 80 | 4 | 6.3 | 8.92-9.16 |

| T602-100080-M10x1 | M10 | 1 | 24 | 38 | 10 | 80 | 4 | 8 | 8.92-9.16 |

| T602-080080-M10x1.25 | M10 | 1.25 | 24 | - | 8 | 80 | 4 | 6.3 | 8.65-8.91 |

| T602-100080-M10x1.25 | M10 | 1.25 | 24 | 38 | 10 | 80 | 4 | 8 | 8.65-8.91 |

| T602-080080-M10x1.5 | M10 | 1.5 | 24 | - | 8 | 80 | 4 | 6.3 | 8.38-8.67 |

| T602-100080-M10x1.5 | M10 | 1.5 | 24 | 38 | 10 | 80 | 4 | 8 | 8.38-8.67 |

| T602-100089-M12x1.25 | M12 | 1.25 | 29 | - | 10 | 89 | 4 | 8 | 10.65-10.91 |

| T602-120089-M12x1.25 | M12 | 1.25 | 29 | 46 | 12 | 89 | 4 | 10 | 10.65-10.91 |

| T602-100089-M12x1.5 | M12 | 1.5 | 29 | - | 10 | 89 | 4 | 8 | 10.38-10.67 |

| T602-120089-M12x1.5 | M12 | 1.5 | 29 | 46 | 12 | 89 | 4 | 10 | 10.38-10.67 |

| T602-100089-M12x1.75 | M12 | 1.75 | 29 | - | 10 | 89 | 4 | 8 | 10.11-10.44 |

| T602-120089-M12x1.75 | M12 | 1.75 | 29 | 46 | 12 | 89 | 4 | 10 | 10.11-10.44 |

| T602-20095-M14x1.5 | M14 | 1.5 | 30 | - | 12 | 95 | 4 | 10 | 12.38-12.67 |

| T602-20095-M14x2 | M14 | 2 | 30 | - | 12 | 95 | 4 | 10 | 11.84-12.2 |

| T602-1120102-M16x2 | M16 | 2 | 32 | - | 12 | 102 | 4 | 10 | 13.9-14.2 |