Molendina finis processus ferro immaculato et calore obsistens admixtos-T502

Finis universalis molendinum pro ferro conflatum GE-Z

| Designatio | D | d | H | L | Z |

| GE-Z-D1.0S | 1.0 | 4 | 3 | 50 | 2/4 |

| GE-Z-D1.5S | 1.5 | 4 | 4 | 50 | 2/4 |

| GE-Z-D2.0S | 2.0 | 4 | 6 | 50 | 2/4 |

| GE-Z-D2.5S | 2.5 | 4 | 8 | 50 | 2/4 |

| GE-Z-D3.0S | 3.0 | 4 | 8 | 50 | 2/4 |

| GE-Z-D4.0S | 4.0 | 4 | 11 | 50 | 2/4 |

| GE-Z-D1.0 | 1.0 | 6 | 3 | 50 | 2/4 |

| GE-Z-D1.5 | 1.5 | 6 | 4 | 50 | 2/4 |

| GE-Z-D2.0 | 2.0 | 6 | 6 | 50 | 2/4 |

| GE-Z-D2.5 | 2.5 | 6 | 8 | 50 | 2/4 |

| GE-Z-D3.0 | 3.0 | 6 | 8 | 50 | 2/4 |

| GE-Z-D3.5 | 3.5 | 6 | 10 | 50 | 2/4 |

| GE-Z-D4.0 | 4.0 | 6 | 11 | 50 | 2/4 |

| GE-Z-D4.5 | 4.5 | 6 | 11 | 50 | 2/4 |

| GE-Z-D5.0 | 5.0 | 6 | 13 | 50 | 2/4 |

| GE-Z-D5.5 | 5.5 | 6 | 16 | 50 | 2/4 |

| GE-Z-D6.0 | 6.0 | 6 | 16 | 50 | 2/4/6 |

| GE-Z-D8.0 | 8.0 | 8 | 20 | 60 | 2/4/6 |

| GE-Z-D9.0 | 9.0 | 10 | 22 | 75 | 2/4/6 |

| GE-Z-D10 | 10.0 | 10 | 25 | 75 | 2/4/6 |

| GE-Z-D12 | 12.0 | 12 | 30 | 75 | 2/4/6 |

| GE-Z-D14 | 14.0 | 14 | 32 | 75 | 2/4/6 |

| GE-Z-D16 | 16.0 | 16 | 45 | 100 | 2/4/6 |

| GE-Z-D18 | 18.0 | 18 | 45 | 100 | 2/4/6 |

| GE-Z-D20 | 20.0 | 20 | 45 | 100 | 2/4/6 |

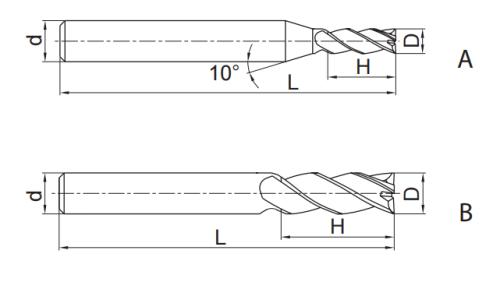

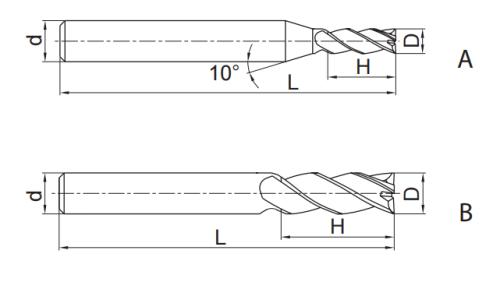

Finis universalis molendinum pro ferro injecto ferro GE-ZL

| Designatio | D | d | H | L | Z | Fig. |

| GE-ZL-D3.0 | 3.0 | 6 | 12 | 75 | 2/4 | A |

| GE-ZL-D4 | 4 | 6 | 15 | 75 | 2/4 | A |

| GE-ZL-D5 | 5 | 6 | 20 | 75 | 2/4 | A |

| GE-ZL-D6 | 6 | 6 | 20 | 75 | 2/4/6 | B |

| GE-ZL-D8 | 8 | 8 | 25 | 100 | 2/4/6 | B |

| GE-ZL-D10 | 10 | 10 | 30 | 100 | 2/4/6 | B |

| GE-ZL-D12 | 12 | 12 | 35 | 100 | 2/4/6 | B |

| GE-ZL-D14 | 14 | 14 | 40 | 100 | 2/4/6 | B |

| GE-ZL-D16 | 16 | 16 | 50 | 150 | 2/4/6 | B |

| GE-ZL-D20 | 20 | 20 | 55 | 150 | 2/4/6 | B |